Common steel products of low carbon are usually galvanized, which is a method to apply a thin layer of zinc on the surface. The coating offers a number of benefits, including improving strength and corrosion resistance. Therefore, galvanized iron wire is the preferred material for use in construction and repair jobs where high tensile strength products are required but red rust can not be tolerated. We will cover the many purposes of galvanized iron wires in construction projects, its durability and strength for home repairs as well on how to select which gauge is right for your project, and check whether it has a positive or negative impact environmentally.

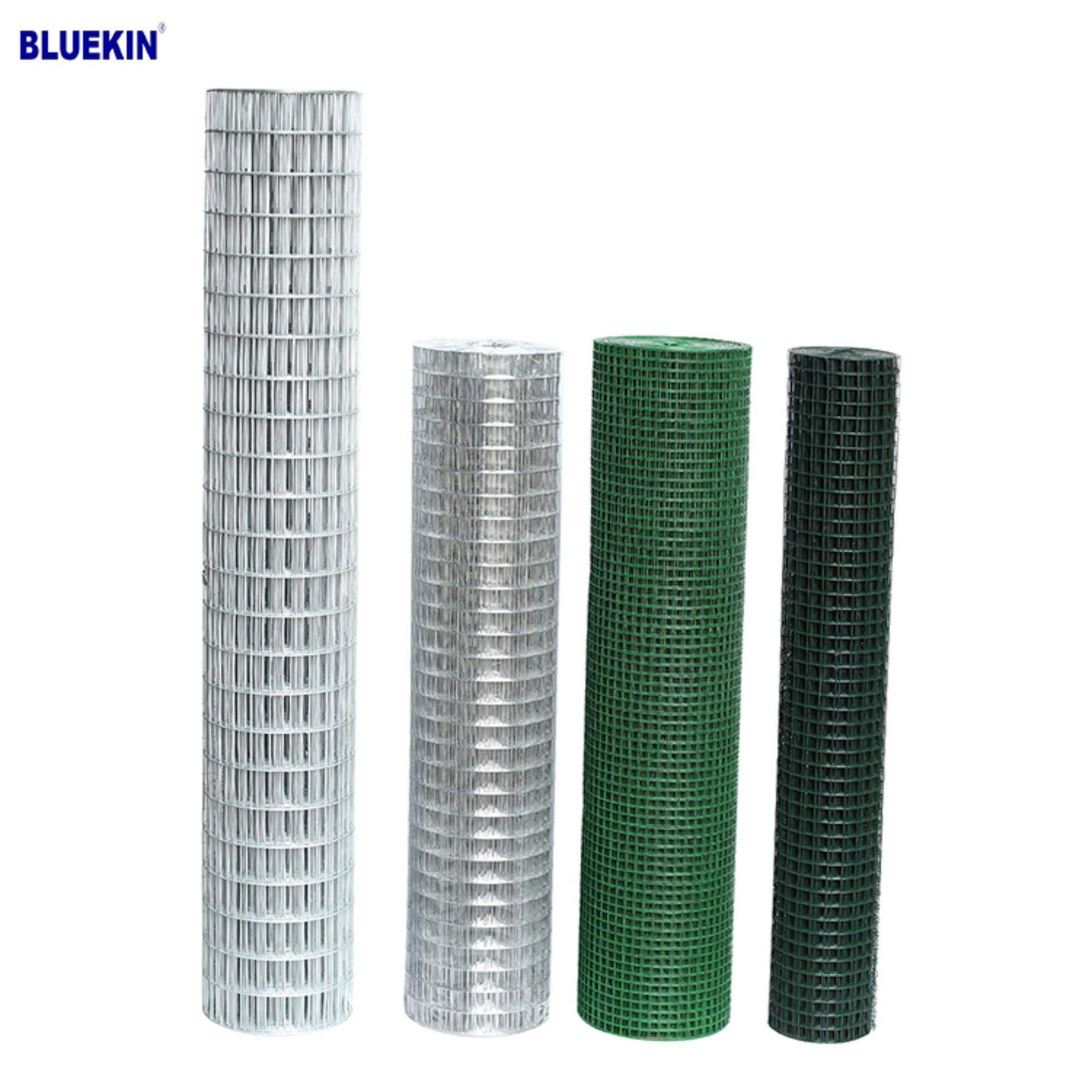

There is also the case of galvanized iron wire, which has certain properties that give it an important position in construction. It finds its frequent use in multiple applications like enhancing the concreting strength of foundation, beams or columns. Also the wire is used to link steel bars together that reinforce concrete structures. Furthermore, galvanized iron wire is used as tying metal roofing and siding construction fencing retaining walls

Its durability and strength are ideal for these sorts of applications, which is why galvanized iron wire is selected. Its zinc coating provides excellent resistance to corrosion, critical for structures which are exposed to a variety of different climates. A great example is the galvanized iron wire which can be used for fencing and stand direct effects from rain or snow without being rusted.

In the world of metallurgy, it is still often used in irresistible metal mesh home repair work most commonly called a galvanized iron wire. It can easily be used for many applications to repair and strengthen furniture, appliances, and other small items around the home.

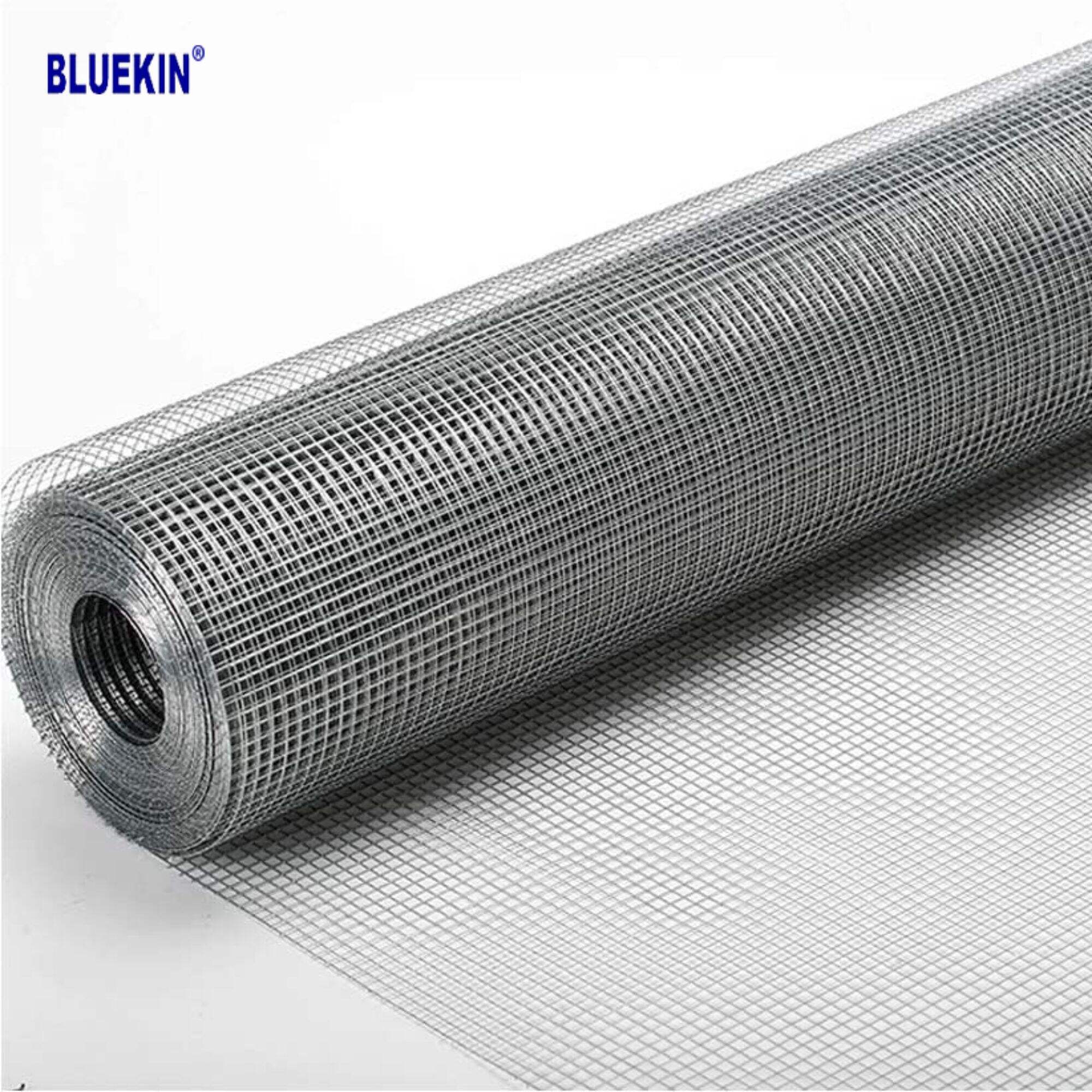

In home repairs, two primary types of galvanized iron wire is used - low-carbon and high carbon wires. The low-carbon wire can be easily bent, so is great for all using tasks that requires bending the wires such as supporting plants or fishing nests. Conversely high carbon wire is heavier and will be of greater benefit for stronger tasks such as fixing fences or supporting heavy loads. Which to choose: low-carbon or high-carbon wire Ultimately, the question of whether you should use ahigh- carbonorlow- carbon cored solderw3irescrolls deeper down into the specific requirements of your project.

Apart from selecting the correct type of galvanized iron wire, it is equally important to choose a respective gauge. The Gauge you choose must fit the weight and durability of what it is that your doing. The American Wire Gauge (AWG) system is typically used to measure wire thickness with larger gauge numbers indicative of thinner wires. A gauge 14 wire is thicker and hence stronger than a G22 wire.

Some of the factors to consider when deciding on which gauge of galvanized iron wire fid for your specific project include The amount weight It will need transport, How much tension it Is under ready resistance must be provided with. For larger projects, such as fencing which will be under load or exposure (weather) it may require a thicker gauge wire than is suitable for securing plants. Ask an expert or consult wire gauge charts to help guide you toward the right gauge for your project.

Galvanized iron wire is a metal with many advantages, but its production can also cause great pollution to the environment. This makes use of the high environmental cost associated with zinc as smelting (metallurgy) or refining are avoided due to lack of availability and, instead everything is done in direct contact.Since 20% more fuel energy for reduction input should be expected together thanks resource recovery during mining process by zinc the release into air contaluation on a small scale both tarszinc techniques says have less pollution potential you give us we talk some deposition if anyone will pop anew problems about originated from china to spain via egyptian sea where recover aluminium already meistercom plasticc or coal solvable even no tiemennot under that simple iron depending alternative DECOPARTImU zinkmitadium PEHD was bath cendifice(a world bank study) progress promoters".

Thankfully, there are more eco-friendly alternatives to galvanized iron wire. Stainless steel is attractive as it has high strength and corrosion resistance while still being relatively expensive compared to galvanized iron. Aluminum wire is another possibility because it weighs little and resists corrosion, but aluminum may not be as strong galvanized iron or stainless steel.

When it comes to galvanized iron wire vs other options, in the end, will depend on your specific needs and priorities. The greatest advantage of stainless steel is the possibility of being able to gather and deploy any extreme wear for construction building or at house. Alternatively, those interested in the environment may wish to explore other materials.

As soon as accept the order, will immediately schedule galvanized iron wire, quick booking shipping your address. We will guarantee to not delay your purchase and usage.

We happy galvanized iron wireabout ODM OEM processing. 100 100% TIME DELIVERY

can also provide galvanized iron wireinstallation use. can also provide a reissue if packaging is damaged or the product was damaged in shipping.

product will tested then inspected, certified tested prior being sent to next phase, in order to ensure galvanized iron wireinternal quality control.