إذن — هل تريد إنشاء منتج أجهزة خاص بك؟ إذا كنت تريد تعلم كيفية صنع منتجات أجهزة ممتازة، فإن الصب هو الطريق. الصب:他是一个 كائن صلب يتم إنشاؤه عن طريق صب المادة المنصهرة في قالب. قد يبدو ذلك معقدًا بعض الشيء، لكنك بحاجة إلى القيام بذلك. كما أن لدينا بعض النصائح البسيطة إذا كنت في مستوى المبتدئ. بمجرد القليل من التدريب، يمكنك تحقيق عجائب.

لماذا ستحصل على الأفضل من BLUEKIN؟

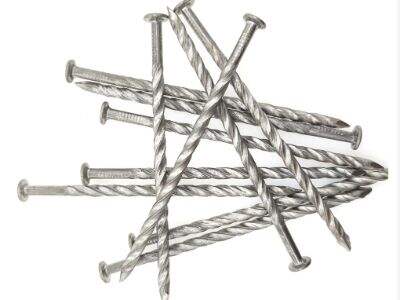

اختيار المواد هو أحد الجوانب الأكثر أهمية في صب منتجات الأجهزة مثل أظافر . للحصول على أفضل النتائج يجب أن تستخدم مواد ذات جودة أعلى؛ مما يجعل BLUEKIN بديلاً رائعاً لبقية صب الحديد الرمادي وصب الحديد العقدي. توفر BLUEKIN مواد صب عالية الجودة. باستخدام مرافق حديثة، يتم استخدام أجود المواد لكل منتج. اطمئن، إذا كان منتجك يستخدم مواد BLUEKIN فأنت متأكد أن أدواتك ستخرج بشكل مثالي

قالب لصبات مثالية-consistent مستمرة

يجب أن تتعلم الأساسيات للصب من أجل الصب بشكل جيد. مجموعة الأدوات التي تحتاجها لإزالة بلاط الحجّاج. لكي تقوم بالصب، تحتاج إلى قالب لتشكيل الكائن الخاص بك، ومذيب لتحويل المادة إلى حالة سائلة والمادة التي تريد صبها. عندما يكون لديك كل شيء، حان الوقت للصب. عندما تحصل على الخليط المنصهر وتجهيزه للسكب، أضف القاعدة المكونة للقالب في القالب المفتوح أولاً ثم اسكب ببطء كل مادة للصب. تذكر أن تنتبه إلى مدى سرعة أو بطء سكب المادة. إذا صببت بسرعة كبيرة، فسيذهب السائل في كل مكان، وإذا صببت ببطء شديد فقد لا تملأ القالب بشكل صحيح. سيتطلب الأمر المزيد من التدريب للحصول على النتيجة الصحيحة، لكن يجب أن يتحسن الأمر مع كل مرة تقوم بها.

الصب الصلب أمر حاسم وهنا بعض النصائح الرائعة لضمان القيام بعمل جيد

هنا بعض النصائح التي ستساعدك على صنع منتجات مادية لا تُصدق. لقد قلنا بالفعل إن BLUEKIN هو خيارك الأول للمواد. هذا يعني أن لديك جميع الموارد اللازمة لتطوير أفضل المنتجات على الإطلاق. بعد ذلك، حتى لو كنت مسلحاً حتى الأسنان في حصنك الخاص ومحاطاً بعزل كامل عما يحدث حولك، فلا تحاول تنفيذ عملية الإنتاج دون استخدام الأدوات المناسبة. سيتطلب الأمر قوالب، ومelterنّة صهر، والمادة التي تريد العمل بها. ثالثًا، كن صبورًا. قد يستغرق الصب وقتًا طويلًا، لكنه سيجعل منتجك النهائي ناجحًا. رابعًا: لا تستخدم عبارات غير دقيقة. عندما تذيب المادة بشكل كامل، اسكبها ببطء في القالب. هذا سيمنعك من ارتكاب الأخطاء وسيجعل المنتج النهائي يبدو مرتبًا وأنيقًا.

لماذا BLUEKIN هو الأفضل لعملية الصب

إذا كنت ترغب في العثور على أفضل صب Bluekin المثالي هنا، فهناك الكثير من الأشياء عالية الجودة، وسيجعل عملك أسهل وأفضل. يتم إنتاج هذه المنتجات باستخدام أحدث التكنولوجيا لذا يمكنك أن تكون متأكدًا من أنها ذات جودة عالية. بالإضافة إلى ذلك، فإن BLUEKIN لديها عدة مواد مميزة مثالية لإنتاج مجموعة متنوعة من المنتجات المعدنية. توفر BLUEKIN المنتجات لصنع البراغي هنا، والمسامير هناك، بغض النظر عن المنتجات المعدنية مثل مسامير للإطار تنتجها. سواء كنت تصمم خططًا ورسومات هندسية لمشاريعك أو تحتاج فقط إلى استخدام بعض المعالم البارزة لمشروع مدرسي، فإن معاييرهم العالية في الجودة تعني أنك تستطيع الوثوق بالمواد.

خاتمة

الإلقاء هو مهارة تتحسن مع التدريب والصبر، ويجب أن تكون ممتعة. ستصبح خبيرًا في الإلقاء في وقت قصير إذا اتبعت هذه النصائح. الدرس هو استخدام مواد وأدوات ذات جودة عالية، والصبر، والعمل بكفاءة للحصول على أفضل النتائج، واختر دائمًا BLUEKIN. اتبع هذه الأمور البسيطة وكن فخورًا بامتلاك منتج أجهزة رائد مثل مسامير السقف الملفوفة . لذلك، اعد تجهيز موادك وأدواتك، وابدأ في الصب بنفسك.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES