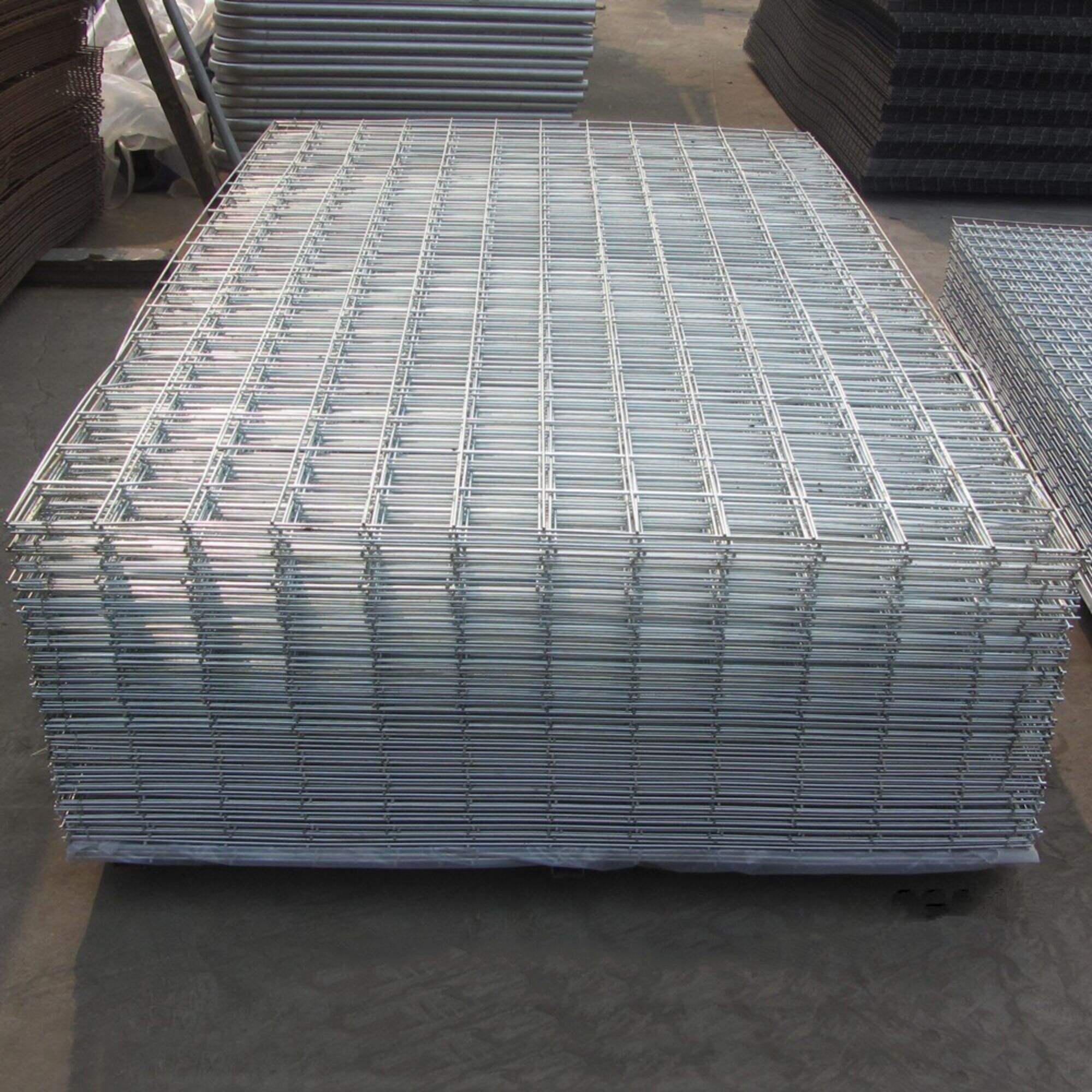

Ein starkes und belastbares Material. Stahlgewebtes Drahtgitter ist ein erstaunlich widerstandsfähiges Material, das in einer Vielzahl von Industrie- und Gewerbebereichen eingesetzt werden kann. Es wird aus hochwertigem Stahl hergestellt, um ein komplexes Gitternetz zu bilden, das sowohl stark als auch flexibel ist. Dieses Produkt kann seine anpassungsfähigen Eigenschaften in vielen verschiedenen Anwendungen zur Geltung bringen. Die verschiedenen speziellen Merkmale machen es zu einem der vielseitigsten Drahtgitterprodukte, die in vielen unterschiedlichen Bereichen eingesetzt werden können, von schwerem Sieben bis hin zu feinem Filtern sowie zäune- und Sicherheitslösungen.

Stahlgewobenes Drahtgitter - Spitzenleistung im Sieben und Filtern, Now()

Eisengewobenes Drahtgitter ist die beste Wahl für Test- und Filteraufgaben. Es ist unverzichtbar für die industrielle Gradierung, da es schnell verschiedene Materialien sortieren und gradieren kann. Die Gewebe-Technik macht das Gitter sowohl gegen Stoß als auch gegen Verschleiß beständig, was es für schwere Anwendungen in Vibrations-Siebsystemen und industriellen Siebern geeignet macht.

Es ist genau diese Vielseitigkeit, die das stählerne Gewebnetz zu einer beliebten Wahl in vielen Industriezweigen gemacht hat, einschließlich der Medizin- und Landwirtschaftsindustrie, wo Stärke, Haltbarkeit und Flexibilität alle wichtige Attribute sind. Dies erweist sich als hilfreich, ob im Landbau, Bergbau, Bauwesen oder in der Fertigung. Darüber hinaus wird es in Branchen wie Öl- und Gasgewinnung, Lebensmittelverarbeitung, Abwasserbehandlung usw. eingesetzt. Die Verwendung von stählernem Gewebnetz ist sehr breit, und der Schutzeffekt ist ausgezeichnet, von der Förderbandabdeckung bis zur mit Beton gefüllten Struktur.

Zaun- und Sicherheitsverwendung von Stahl-Gewebnetz

Weniger stark im Vergleich zur Welt der Umzäunungen und Sicherheit, bleibt Drahtnetz aus Stahl dennoch standardmäßig aufgrund seiner unübertroffenen Zugfestigkeit. Dies macht es zu einem großartigen Produkt für langanhaltende Zäune, umzäunende Bereiche, die robust und sicher sein müssen, sowie andere Arten von Barrierefassaden. Das Netz selbst ist sowohl stark als auch flexibel, was bedeutet, dass es sowohl für temporäre als auch für permanente Zäunungslösungen verwendet werden kann. Wenn Sie unter weniger überwachten Bedingungen oder an einem belebten Ort in Sicherheit bleiben müssen, ermöglicht das durchsichtige Design eine einfache Beobachtung durch Sicherheitsposten, Zugangskontrollpunkte und Baustellen.

Die Auswahl des richtigen stählernen Gewebenetzes kann einschüchternd sein bei all den Optionen auf dem Markt. Hier sind einige Faktoren zu berücksichtigen:

Netzgröße: Die Anzahl der Drähte innerhalb eines Quadratzoll-Netzes zeigt Gefahr oder Bedrohung.

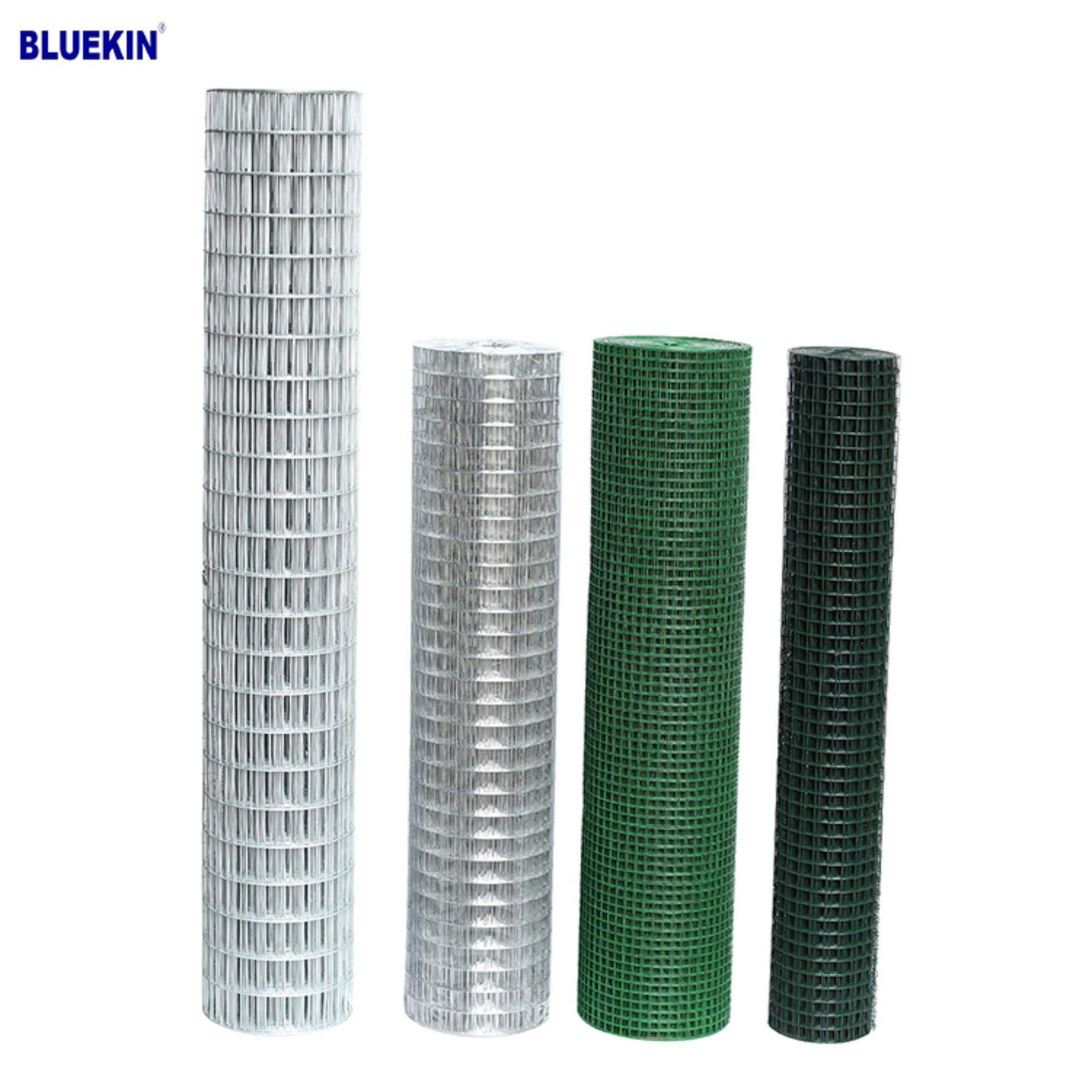

Materialcharakteristik: Verschiedene Materialien wie Edelstahl oder galvanisiertes Stahl haben einen Einfluss auf die Haltbarkeit und Rostbeständigkeit eines Netzes.

Stahlgewebtes Drahtgitter ist ein multifunktionales Material und bietet viele Vorteile für verschiedene Anwendungen in verschiedenen Branchen. Seine Stärke, Widerstandsfähigkeit und Flexibilität machen es zu einem hervorragenden Werkzeug in der Arbeitswelt für Sieb-Aufgaben (Trennung und Raumabgrenzung), Filtrierung oder Zaunbau sowie Schutz. Das richtige Netz für die gewünschte Verwendung auswählen: Drahtdickheit, Maschengröße und Material beachten.

produkte unterliegen strengen Prüfungen und Untersuchungen in jedem Prozess durch Mitarbeiter der Qualitätssicherung (QC) für stahlgewebte Drahtgitter periodisch, beginnend mit den Rohstoffen, die dem Werk zugeführt werden. Die Produkte werden geprüft und getestet, um sicherzustellen, dass sie genehmigt werden, bevor sie in den nächsten Prozess gehen, wodurch die interne Qualitätskontrolle gewährleistet wird.

Wir bieten bei stahlgewebten Drahtgittern ODM- und OEM-Verarbeitung an. 100% ZEITGEBUNDENE LIEFERUNG

Wir können Bedienanleitungen und Installationsvideos bereitstellen. Wenn das Produkt mit beschädigtem stählernem Geflecht durch den Transport beschädigt ankommt, werden wir es Ihnen zurückschicken, um sicherzustellen, dass Sie es verwenden können.

werden die Produktion innerhalb kürzester Zeit nach Eingang der Bestätigung für das stählerne Geflecht planen.