As-tu vu ce grand marteau et ce clou sur le chantier ? Ce clou est, quite littéralement... le clou de charpente courant ! Un style de fixateur que les entrepreneurs utilisent pour joindre deux parties de bois. Les clous de charpente courants sont plus longs que les clous de taille normale et existent en plusieurs longueurs. En fonction de la dimension, un clou est choisi pour fixer du bois. C'est pour du bois lourd, afin qu'il ne se casse pas, il te faudra un clou plus long et aussi plus large.

Voici quelques-unes des questions cruciales à lesquelles chaque propriétaire doit répondre lors d'un contrôle du constructeur au moment de choisir un clou de charpente (apparemment, c'est une tâche ennuyeuse) : si les clous sont trop courts, il faudra recommencer la recherche pour en trouver d'autres. Cela signifie que le clou doit être assez long pour traverser complètement un morceau de bois et pénétrer dans un second ; Sinon, s'il est trop court, il ne disposera pas de la force nécessaire pour maintenir le bois assemblé (là où vous pourriez rencontrer du verre_à_vous). De plus, le clou doit être adapté en profondeur. Si c'est un morceau particulièrement épais, il faudra utiliser un clou avec des crans plus larges qui peuvent bien s'accrocher dans le bois. Ce n'est qu'après cela qu'ils considèrent la composition du clou. Certains clous peuvent supporter plus de pression car ils sont fabriqués à partir de matériaux plus solides que d'autres. Avant tout, les dimensions doivent correspondre au matériau sélectionné pour une utilisation donnée.

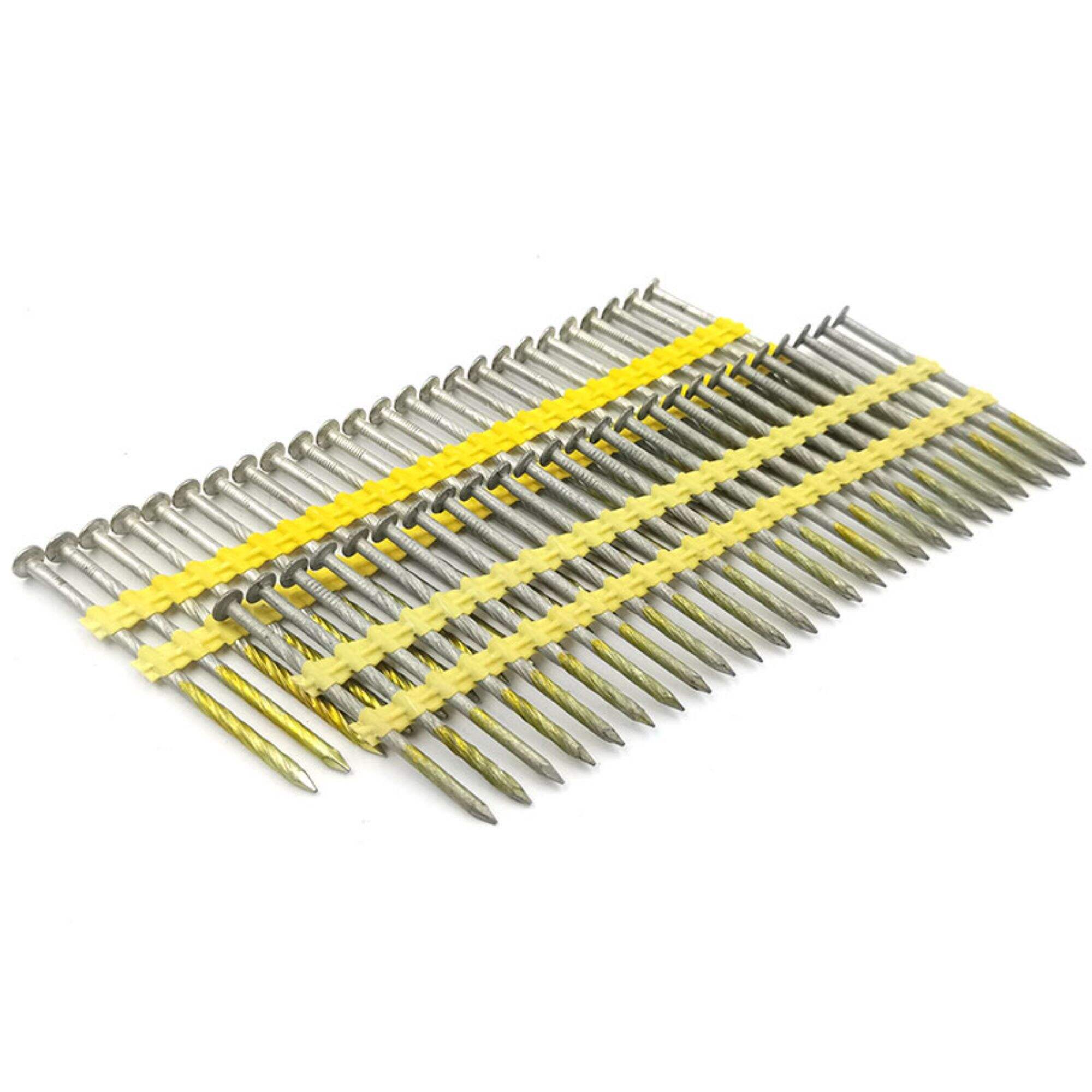

Clous de charpente courants Clous de Charpente Courants 16 Vous pouvez parier que la plupart des projets de construction nécessiteront des clous de charpente courants. Un avantage majeur de ce type est qu'ils sont très solides, donc ils peuvent se maintenir entre eux et supporter un chargement encore plus élevé que les types mentionnés précédemment. De cette manière, l'ensemble du travail de construction devient beaucoup plus sûr et encore plus fiable. Les constructeurs accomplissent leur tâche plus rapidement avec des clous de charpente standards. Cela est dû au fait qu'ils n'ont pas besoin de se fatiguer en reprenant constamment les dimensions ni d'ajuster continuellement le poids des matériaux de finition pour qu'ils s'assemblent tous ensemble. Ils devraient donc plutôt utiliser ces clous pour fixer solidement tout ensemble afin que le projet puisse être terminé plus rapidement.

Clou de charpente le plus choisi. L'un des points clés concernant les clous de charpente est qu'ils utilisent (.. annulant..) 'moyenne...in')... Un fait qui nécessite la taille de clou parfaite pour votre travail du bois comme ('=DEFAULT''='') Quantité 3. Vous pouvez ensuite aligner ces morceaux de bois et centrer le clou sur les deux couches uniformes. Ensuite, il faut l'enfoncer dans le bois. Vous êtes également moins susceptible de frapper le clou droit, ce qui contribuera à le maintenir plus solidement. De nouvelles brossettes moteur sont toujours vendues par paires, et surveillez que les clous ne soient ni trop lâches ni trop serrés. Tout ce que cela fera, c'est casser la zone d'ancrage et créer des fissures dans d'autres zones. Lorsque le clou est lâche, il ne peut pas fixer solidement les morceaux de bois ensemble, ce qui les fera tomber; dans un état fragile.

Cependant, comme chaque maçon le sait et l'admet, les clous ordinaires sont souvent le meilleur choix pour de nombreux projets de construction, mais ils ont d'autres options. Par exemple, ils peuvent utiliser des vis plutôt que des clous pour la construction. Les vis sont également plus solides, donc elles supportent plus de poids que la plupart des clous et constituent ainsi un excellent choix pour les travaux lourds. Cela dit, les vis sont généralement plus coûteuses et prennent plus de temps à installer car il faut les visser dans le bois. Lorsque les pièces en bois doivent simplement être collées ensemble, vous pourriez même envisager d'utiliser de la colle et ne pas les visser ou les clouer du tout. Coller : C'est comme si vous vouliez visser ou clouer quelque chose, mais cela ne tient pas bien sous de lourdes charges et nécessite un temps de séchage.

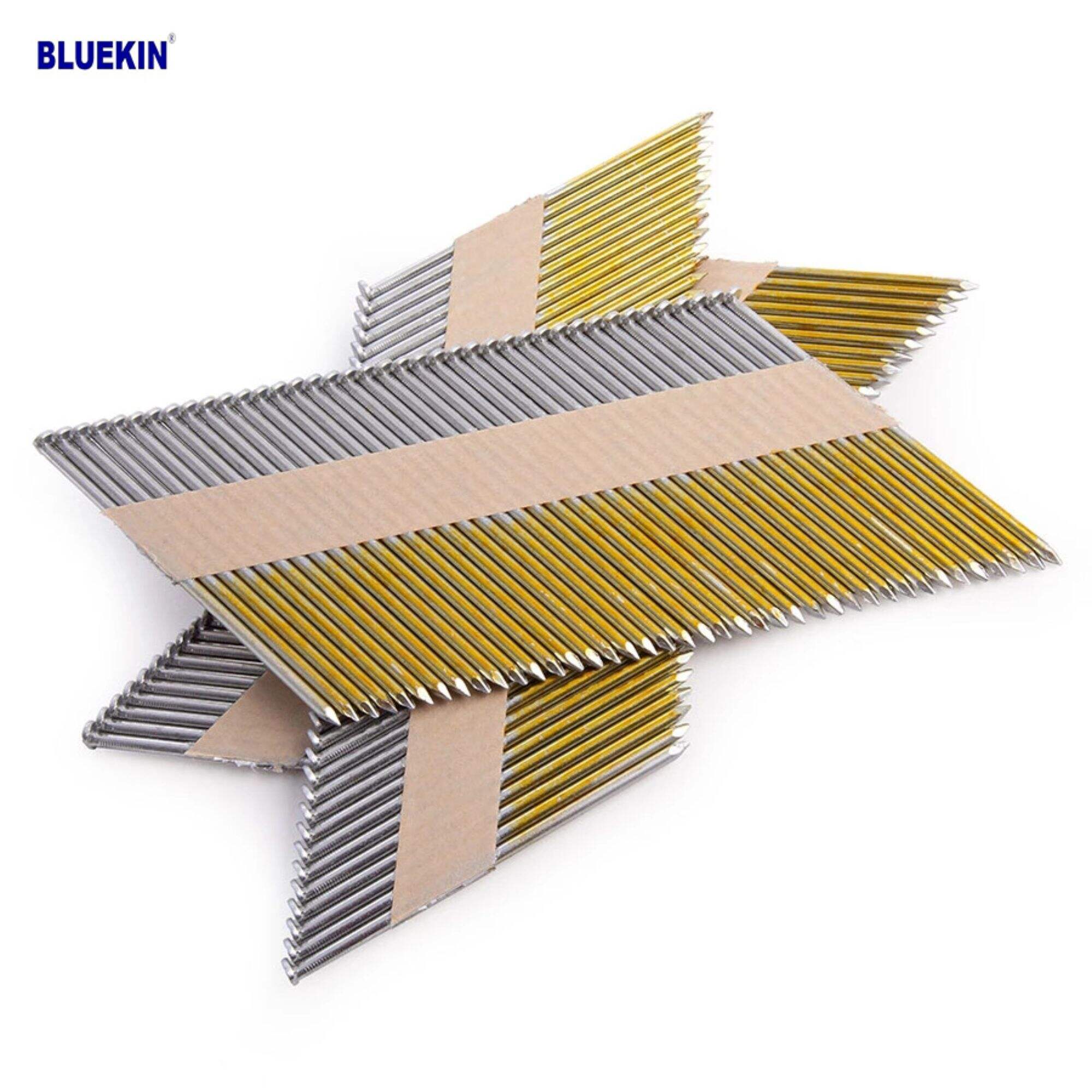

conception inclut la conception de clou de charpente commun, conception de structure emballage. peut créer les produits dont vous avez besoin. Bienvenue pour discuter du traitement ODM ainsi que du traitement OEM. LIVRAISON 100 % À L'HEURE

production de clous de charpente commune sera effectuée dans un délai de quelques heures après réception de la confirmation de commande.

Nous sommes en mesure de fournir un manuel utilisateur et des vidéos d'installation. Si le produit arrive avec des dommages au clou de charpente commun dus au transport, nous vous le rembourrons pour vous assurer que vous pouvez l'utiliser.

le produit sera testé puis inspecté, certifié après des tests avant d'être envoyé à la prochaine phase, afin de garantir le contrôle qualité interne des clous de charpente standard.